The flexural strength dielectric constant and loss tangent values of various ceramic materials used in the development of radomes are important in the selection of radome materials.

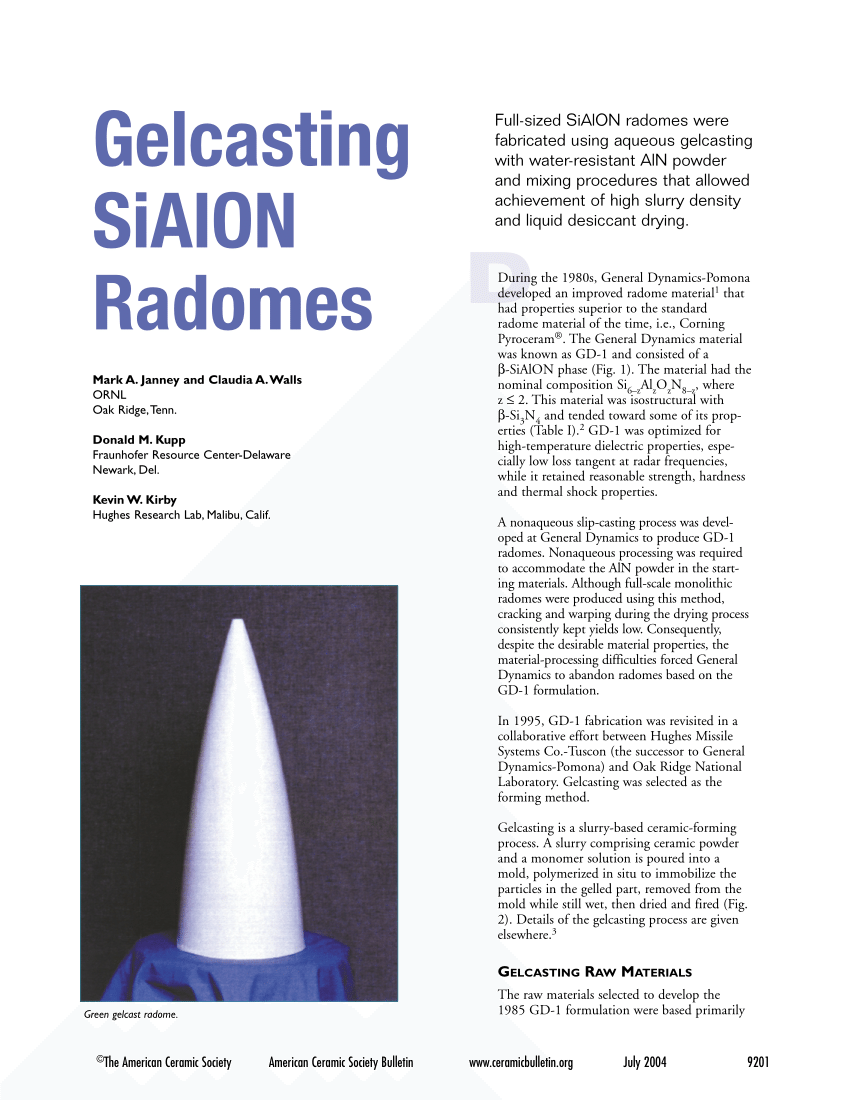

Ceramic radome material.

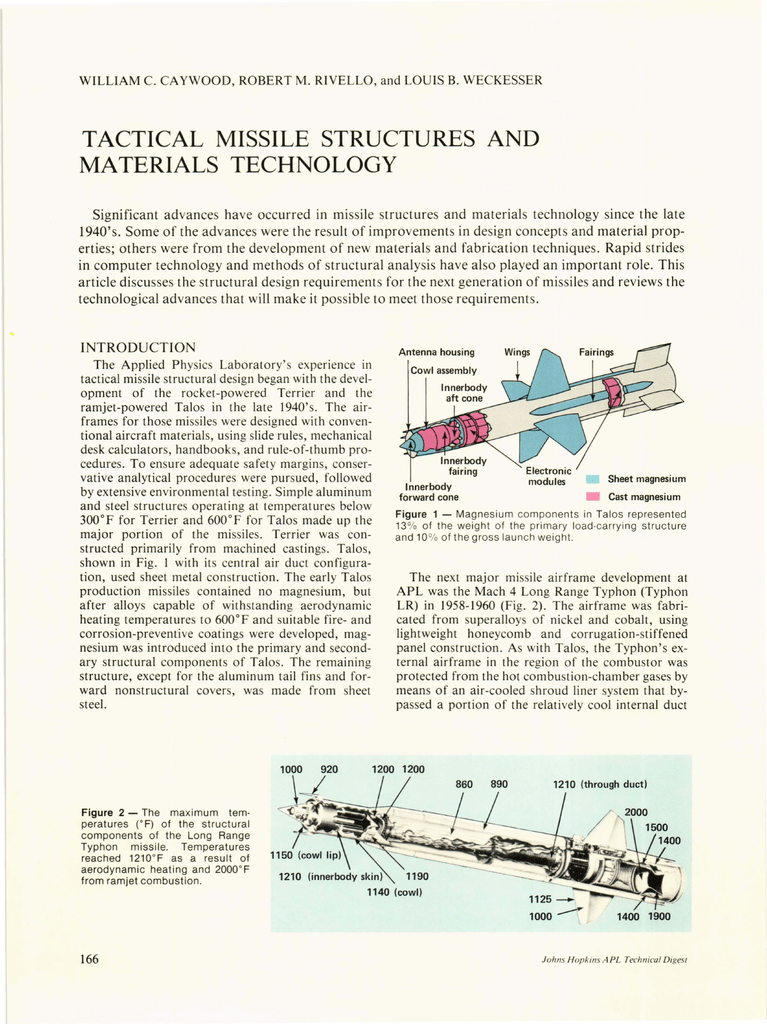

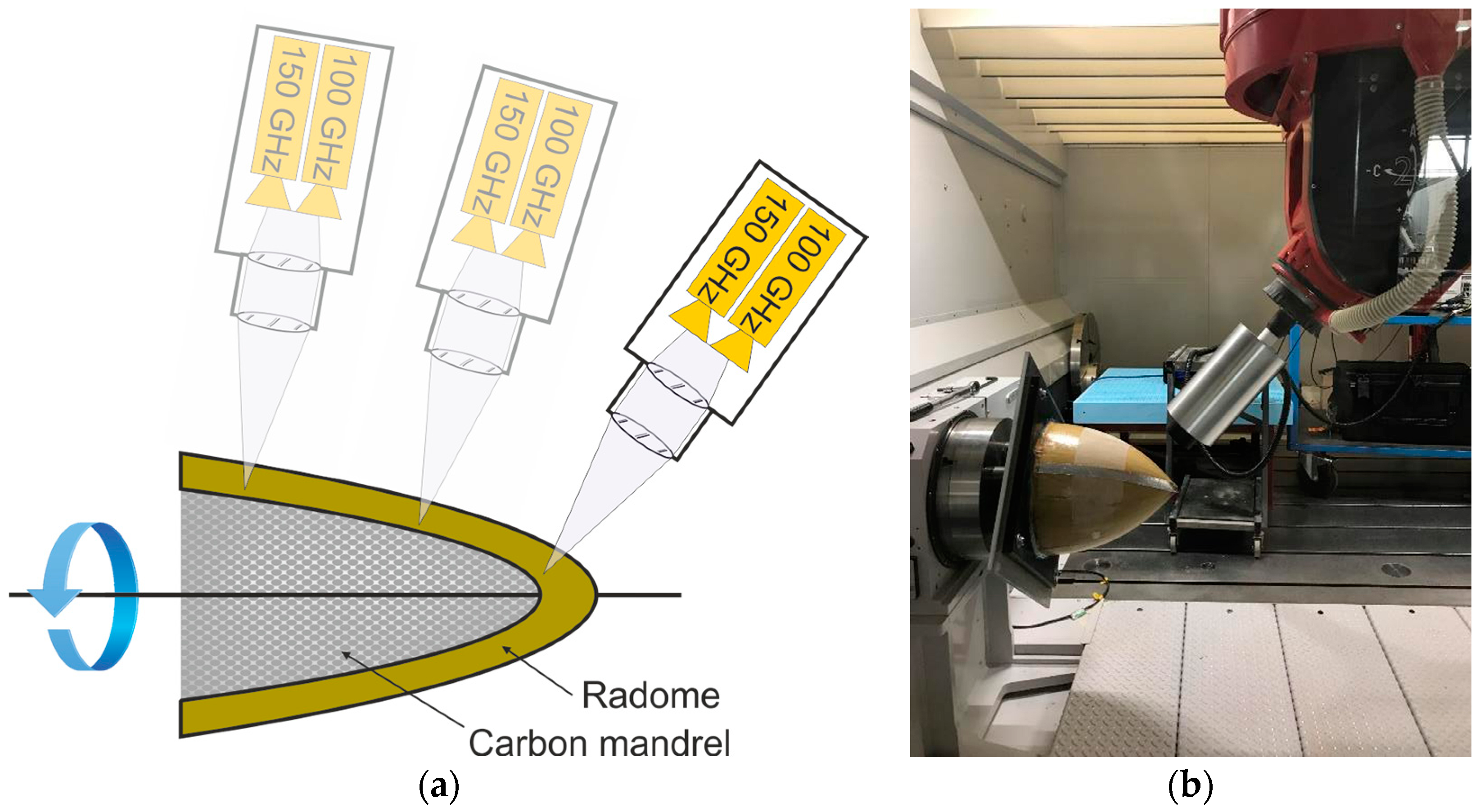

The radome is the most widely used ceramic matrix composite material in missile structure.

That is made from a single layer of material.

Silicon nitride si3n4 ceramic is a promising ultra high speed 5 mach broadband 1 18 ghz radome material because of its excellent high temperature resistance good mechanical and dielectric.

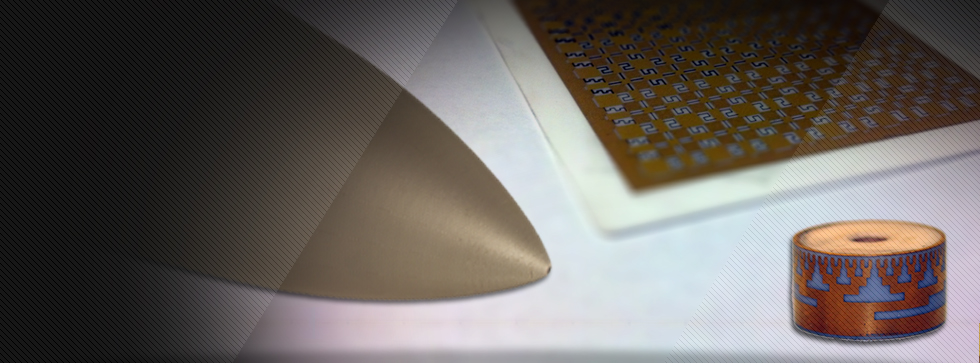

Different nose cone shapes of missile radomes are also important.

Easily optimized material allows for high performance with low dielectric interference.

In all radome applications polyurethane foams offer an effective solution for cost effective materials that are both versatile and robust.

The glass ceramic material produced by corning since the 1950s is opaque gray in color and has high strength high elastic modulus and uniform dielectric properties.

Ceramic radomes flying today are monolithic.

Corning produces a proprietary material corning pyroceram for use in missile radomes.

Ceramic material is the preferred material for missile radome because of its excellent mechanical thermal and electrical properties.

Polyurethanes are especially useful in aerospace applications where functional lightweight materials are imperative.

The missile radome is located at the front end of the missile.

This effort will leverage nanosonics rapidly evolving polymer derived ceramic hybridsil nanotechnology which has demonstrated thermo.