A regenerative heat exchanger or more commonly a regenerator is a type of heat exchanger where heat from the hot fluid is intermittently stored in a thermal storage medium before it is transferred to the cold fluid.

Ceramic recuperative heat exchanger.

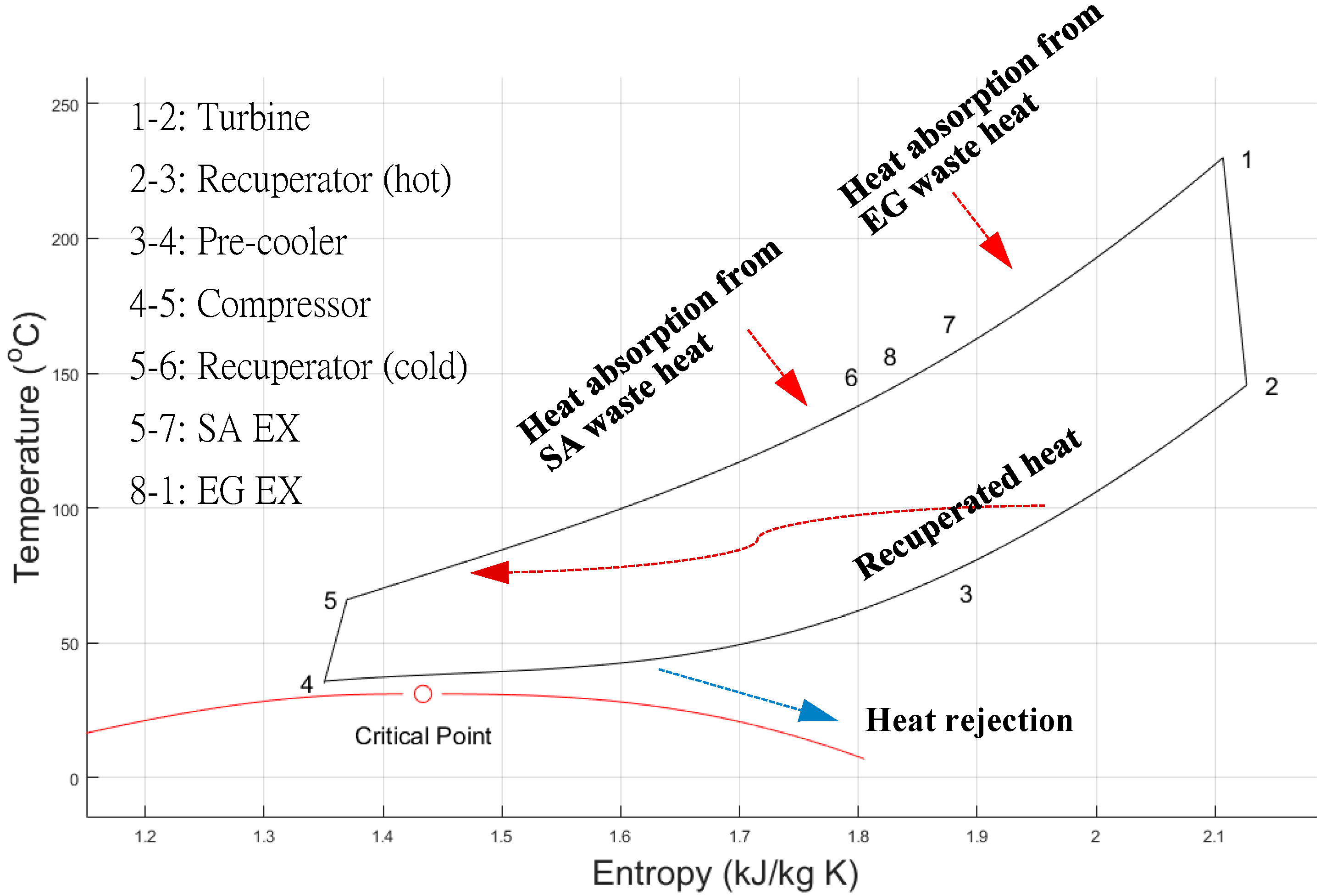

A compact plate type recuperative heat exchanger feasible in metal or ceramic materials and suitable for stationary and vehicular gas turbines is described.

Us3176763a us16781762a us3176763a us 3176763 a us3176763 a us 3176763a us 16781762 a us16781762 a us 16781762a us 3176763 a us3176763 a us 3176763a authority us united states prior art keywords plates spacer strips strips heat exchanger sealing prior art date 1961 02 27 legal status the legal status is an assumption and is not a legal conclusion.

To accomplish this the hot fluid is brought into contact with the heat storage medium then the fluid is displaced with the cold fluid which absorbs the heat.

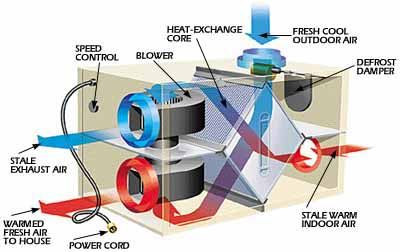

A recuperator is a special purpose counter flow energy recovery heat exchanger positioned within the supply and exhaust air streams of an air handling system or in the exhaust gases of an industrial process in order to recover the waste heat generally they are used to extract heat from the exhaust and use it to preheat air entering the combustion system.

Devices involving energy sources such as nuclear fuel pins or fired heaters are not normally regarded as heat exchangers although many of the principles.

The main difference between a regenerative thermal oxidizer rto and recuperative thermal oxidizer is the different methods they use for heat recovery in the system.

The technology used includes tape casting punching lamination and embossing as well.

Regenerative oxidizers pass hot exhaust gas and cooler inlet gas through one or more heat exchanger beds containing ceramic media.

The hot flue gases are fed through the ceramic or metallic heat exchanger which is integrat ed in the burner heating the additional supply of cold combustion air flowing in the opposite direction.

A heat exchanger is a device used to transfer heat between two or more fluids.

The ceramic heat exchangers are used in applications with higher process temperatures or with high thermal loads.

The development of silicon nitride recuperative heat exchangers hx for gas turbine application heat technology process engineering and automobile engines as well is described.

The fluids can be single or two phase and depending on the exchanger type may be separated or in direct contact.

Recuperative or regenerative heat exchanger systems which may be integrated in the burner assemblies are commonly used for this purpose.

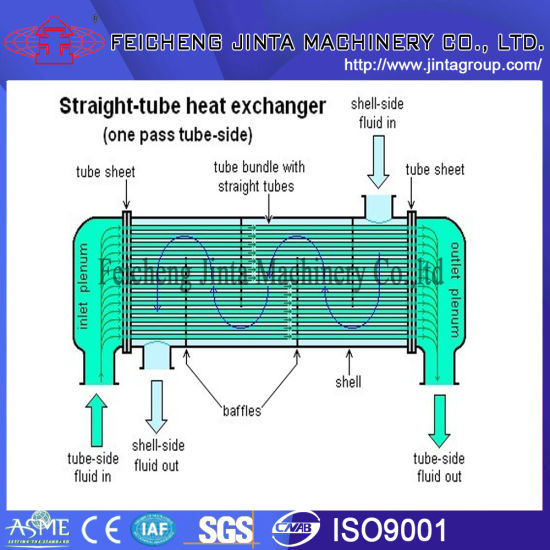

In these heat exchangers a stream of cold process gas passes through a series of tubes and is heated by another stream of gas which passes over the tubes on the shell side.

The flow schemes and fabrication techniques of the heat exchanging matrices are illustrated.

Heat exchanger hx areas up to 2500 m 2 m 3 can be fabricated.

Metallic and ceramic prototype matrices are shown which have been fabricated successfully.